N-1wsletter #15: Garbaruk’s new wheels, the perils of lingering tubeless leaks, and an easy way to predict your tire width

This week’s newsletter includes the usual mix of interesting new product announcements, but also a review of a brilliantly simple (and incredibly useful) little tire tool and a question of how much bi

Featured in this week’s tech round-up:

Stop thinking about it and just go for the bike ride already.

Garbaruk dives into the wheel market.

Pivot ups its warranty game.

A more widely compatible power meter from Rotor.

New crankset bits from Appleman Bicycles.

Chris King wants to brighten up your morning.

OMM, something actually got less expensive???

Zwift links up with TrainerRoad.

It’s almost time for the Philly Bike Expo!

An easy way to predict your tire width without having to install them first.

A bike for… everyone?

Don’t ignore that mysterious tubeless leak.

Mmm… banana bread.

I used to think of myself as a pretty reasonably hardy cyclist when it comes to riding in bad weather. Back when I was living in the American Midwest – and especially when I was in college – I used to ride in rain, snow, cold, heat, humidity, wind, whatever. Basically, if I had the opportunity to ride, I was going to do it, come hell or high water.

Unfortunately, living in Colorado for the last 20 years has made me soft. It’s sunny more often than not, and while the temperature swings can be pretty extreme, the low humidity makes it all more tolerable than you’d expect. It can feel surprisingly toasty when it’s -7°C (20°F) as long as the sun is blazing. It also rarely rains, and even when it does, it usually doesn’t last long. There’s a saying around here that if you don’t like the weather, just wait 20 minutes – and it’s not far from the truth.

Winters are a lot more variable, typically with disturbingly mild days interspersed with brutally cold and snowy ones.

Yesterday was closer to the latter.

The high temperature was a whopping -9°C (15°F), and it was wet and overcast, with intermittent snow. If that sounds cold to you, that’s because it was. I had plans to head out on the fat bike (during the day instead of my usual Tuesday night group ride), but hovering over a warm oven with a fresh prosciutto-and-provolone sourdough boule in between bouts of typing somehow seemed more appealing.

Later that evening, I saw a post from my friend, Dan Harvey. I’m pretty sure Dan is quite literally the smartest person I’ve ever met, with a brain that operates in ways I simply can’t fully comprehend. But he’s also one of the biggest bike nerds you’ll ever encounter, and such an avid fat bike aficionado that he started designing and making his own because he couldn’t find exactly what he wanted (his company is called Rise Bikes, by the way, and well worth a peek).

Dan did get out that day. I’m not sure where, not sure for how long. But between the cold temperatures and sketchy conditions, he said he had the trails completely to himself. “Didn’t see another soul out today,” he wrote. “15F conditions will do that.”

Those are the days we all live for – the days that I usually live for. When it seems like you have the outdoors all to yourself, with nothing to interrupt your thoughts but the sound of your own breathing and your tires rolling across the ground. When it’s so quiet and still that you notice birds flapping the distance, the way the snow gently falls from branches overhead, or how the cows in the distance are just blissfully grazing on wild grasses by the creek. Like you’re a character in your own personal snow globe.

Looking back over my years of riding, I’m not sure I can come up with a single time when I went for a ride and wished I hadn’t. Riding bikes isn’t always the answer, but it’s also never not the answer, either. I remember a mountain bike ride I did a couple of years in conditions not far from what Dan experienced. It was misty and cold, with lots of frost covering everything. Terrible visibility. But there was absolutely no one else out, and at least that afternoon, that trail may as well have been my private backyard. It was glorious.

There will always be legitimate reasons why we can’t head out for a pedal: work, family, and so on. But sometimes, it’s just a lack of motivation. Moral of the story? Just go for the bike ride already.

In the news

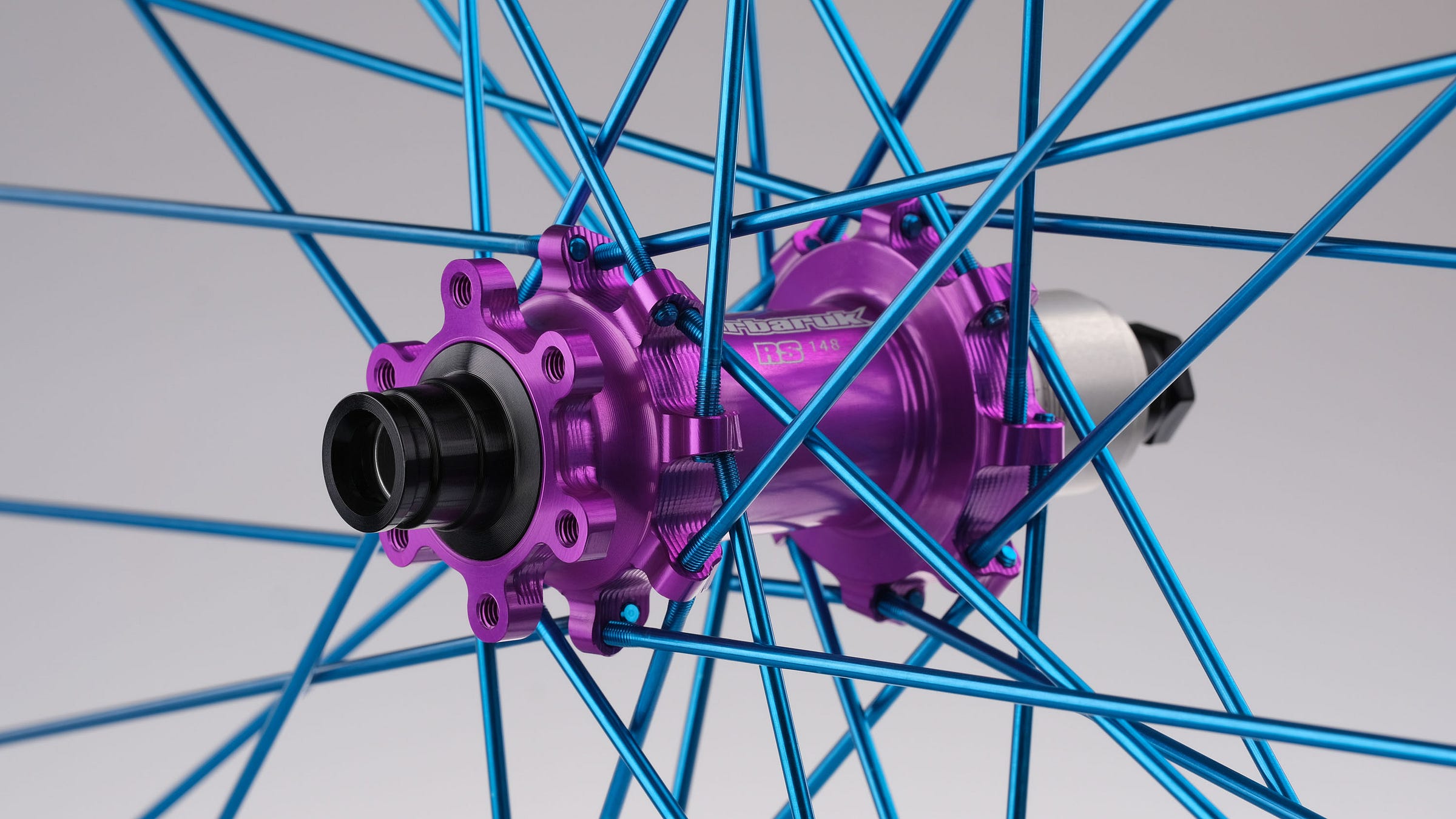

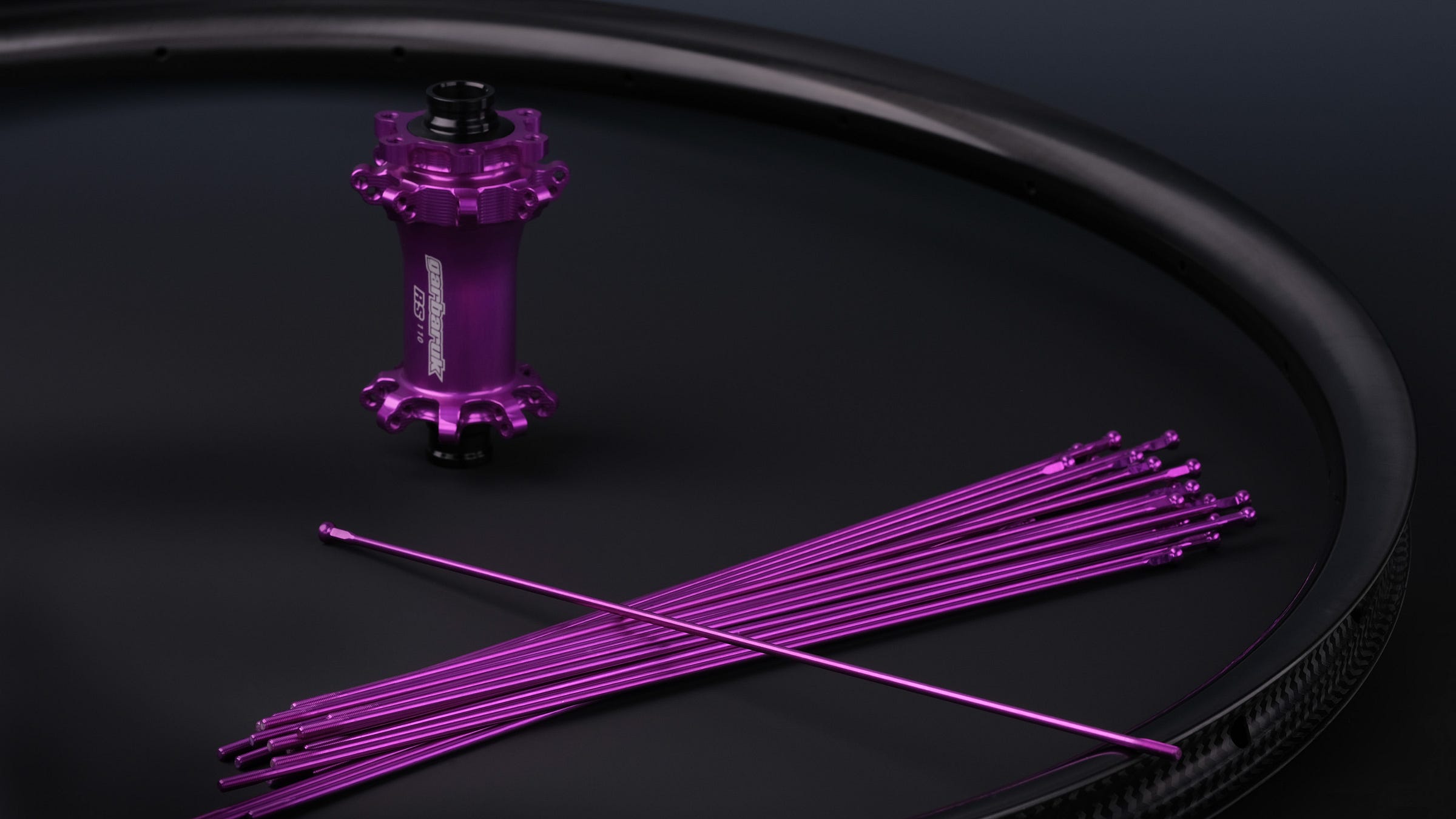

Garbaruk expands into wheels

Polish component brand Garbaruk has been best known for its ultralight cassettes and distinctive machined aluminum cranksets, and it’s now expanding into complete wheels that are more than a little eye-catching.

The new wheels will cover the gravel, XC/downcountry, trail/AM, and enduro markets, all using CNC-machined and anodized aluminum spokes, hubs of Garbaruk’s own design, and carbon fiber tubeless-compatible rims made overseas that are hooked for the gravel model, but hookless otherwise.

“We're not a carbon manufacturer any more so the rims are made for our order, at our own specs, from a big and reliable rim specialist from Fujian, China,” said Tom Skubiszewski of Garbaruk. “[They’re] not made by us and it's ok since they're among the best, and our rims are not sold in their regular portfolio.”

In addition to the rainbow-like array of available colors for both the spokes and hubs, and the surprisingly reasonable price points, what also stands out about Garbaruk’s new wheelsets is their impressively low weights.

Although the rims are made elsewhere, Garbaruk seems to be doing just about everything else in-house.

The machined aluminum hubs are pretty light with claimed weights as low as 115 g for the front and 216 g for the rear. They feature oversized 17 mm-diameter aluminum axles and big cartridge bearings, both of which bode well for durability, especially on full-suspension frames. Hub disassembly is quick for easy servicing – but not too quick. Garbaruk points out that the driveside end cap is threaded on to the axle so there’s no risk of the freehub body and cassette falling off unexpectedly when you remove the rear wheel.

The freehub mechanism is a dual-ratchet design with large-diameter steel drive rings (not entirely unlike DT Swiss’s DEG system) and 60 teeth each for a reasonably quick 6° engagement speed. Those drive rings seem kind of thin to me, though, which gives me some pause in terms of how well they’ll handle abuse and neglect. Time will time. Nevertheless, perhaps as a benefit of producing them themselves, Garbaruk is offering them in the full gamut of modern fitments, including non-Boost (100/142 mm), Boost (110/148 mm), and Superboost (110/157 mm) axle spacings.

As for the spokes, they’re round in profile with a large 2.9 mm diameter, and Garbaruk is making some bold claims in terms of strength and stiffness compared to more conventional (and typically much thinner) stainless steel construction. Whether the stiffness trait is a good thing will be a matter of opinion, particularly given recent trends toward more compliance, not less. Either way, having ridden other wheels with similar construction, I’d say there’s a good chance Garbaruk's claims come to pass.

Durability will be a big question in my mind given the seemingly low rider weight limits and conspicuous absence of impact testing results. But Garbaruk is at least offering a five-year warranty and a crash replacement program (though it’s just a 35% discount to the original owner only), so we’ll see how much either of those are needed.

Speaking of similar construction, though, it’s hard to ignore the elephant in the room. Garbaruk’s new wheel design bears more than a passing resemblance to what Industry Nine has sold for ages, including how the spokes thread into the hub flanges, the claims of increased stiffness relative to wheels built with conventional stainless steel spokes, and even the online color configurator that helps to visualize what your new custom Garbaruk wheels will look like.

Interestingly enough, Garbaruk doesn’t deny that similarity, but insists the situation isn’t what it seems.

“When we started designing our wheels, the goal was to create the best-performing wheels we could, in true Garbaruk style – high performance, low weight, and bold colors,” said Garbaruk co-founder Vladyslav Garbaruk. “For the spokes, we considered all materials, including carbon, drawing from our past experience with carbon components in Ukraine. But after thorough testing, we chose high-performance aluminum alloy. It offers the best balance of strength, weight, and durability for our needs. Since CNC-machining is our specialty, the spokes are straight-pull by design; features like J-bends aren’t possible with this approach. While the look might seem familiar at first glance, the engineering and performance are uniquely Garbaruk.”

Regardless, Garbaruk at least doesn’t seem to be crossing any legal boundaries here.

“Unfortunately, we could not get a patent on our design although we tried in our early days,” Industry Nine vice president Jacob McGahey told me. “There was prior art on direct-thread one-piece spokes going back to wagon wheels. I'm guessing if we had dug deeper we might have been able to get a utility patent, but the company was cash-strapped at the time and additional legal fees weren't in the budget.”

To be clear, aluminum spokes don’t have to be used in this fashion. Mavic and Fulcrum have also both used straight-pull aluminum spokes in the past, for example, and theirs were forged, not machined, with bladed profiles and flared heads that could be more conventionally anchored at the hub. Garbaruk perhaps really didn’t intend to just copy Industry Nine, but the RS wheels are at least a tacit confirmation that it’s a good way to go about it. Regardless, Garbaruk points out there are also countless wheels that use straight-pull or J-bend steel spokes, but no one accuses those brands of copying each other. And even McGahey mentioned that it isn’t clear that Industry Nine could have even secured a patent since Easton already had one for its Velomax wheels at the time, with steel spokes that threaded directly into the hub shell.

So be it. How’s that saying go again about imitation and flattery?

Pivot Cycles announces upgraded warranty policy

Bought a new Pivot Cycles frame or bike recently? Congratulations! Your warranty is way longer than you thought it was. Pivot has just announced that all frames purchased in 2024 onward are now covered by a lifetime warranty in place of the ten-year one that applied previously.

“Effective for bikes sold on or after January 1, 2024, the Pivot Premier Lifetime Warranty offers lifetime coverage on frames for the original owner,” reads the company’s official statement. “This warranty covers defects in materials and workmanship, providing long-term confidence in every ride.”

Bikes have to be registered either within 30 days of purchase or no later than April 1, 2025, to qualify, but any bikes already purchased and registered with automatically be enrolled. And if you really can’t be bothered to fill out some (digital) paperwork, just be aware you’ll otherwise only get three years of coverage.

As icing on the cake, Pivot has also announced a lifetime linkage bearing replacement program. If you’ve got a Pivot frame with a roached linkage bearing, Pivot will send a new one free of charge (with the exception of shipping, presumably), regardless of when you bought it. Pivot is careful to point out that this is not an extension of the warranty and doesn’t cover associated labor costs, though, and it only applies to original owners with proof of purchase.

“With lifetime coverage and courtesy bearing replacements, we’re ensuring that every Pivot rider can enjoy the ride of a lifetime with peace of mind, knowing we’re here to support them for the long haul,” said Pivot president Bryan Mason via press release.

Head here to register for the lifetime warranty program, and here if you need a bearing or two.

Pretty cool.

Rotor announces INspider Road second-generation power meter

Rotor has just unveiled the successor to its INspider DM spider-based power meter, and the numbers look promising.

The new INspider Road boasts a much longer run time from its embedded rechargeable Li-ion battery (350 hours of ride time instead off 200), and it’s also 20 g lighter with a claimed weight of 128 g without hardware. More importantly from a compatibility standpoint, it’s also substantially thinner than the old unit at 12 mm instead of 21 mm, which should greatly reduce the potential for frame interference.

Rotor says the new INspider Road is more advanced in terms of its capabilities, too, with newfound compatibility with Garmin Cycling Dynamics for more granular data analysis. Claimed accuracy is +/- 1.5%.

Carrying over is the same dual-sided measurement as the old INspider DM, as well as Rotor’s Optimum Chainring Position (OCP) splined interface so you can fine-tune your power transmission curve if you’re using non-round chainrings.

Retail price is US$600 / £500 / €600 / AU$990.

Appleman Bicycles expands crankset options with new rings and spiders

Framebuilder Matt Appleman clearly keeps his ear to the ground in terms of emerging trends, launching his modular aluminum 2XR cranks back in 2022 with a huge range of arm lengths that went from 175 mm all the way down to 135 mm (he’s since added a 100 mm option) – not to mention your choice of ten painted colors for the arms and spider. Heck, you can even order a crankset with two different arm lengths if that’s what you need.

Appleman is continuing to build on the made-in-Minnesota 2XR ecosystem, now adding a 110/80 mm, four-arm spider for use with Shimano GRX chainrings, as well as new direct-mount chainrings with a narrow-wide profile that’ll supposedly work with just about any drivetrain from 8-13 speeds.

Neither is remotely inexpensive, with the chainring starting at US$185 and the spider starting at US$125 (for reference, the 2XR crankset is over US$500 without chainrings). That said, I still hold fast to the belief that more options are better.

Bike and coffee worlds collide for Chris King

Chris King has somehow always done a good job of adapting some of its products to a few select non-bike applications, such as the salt and pepper shakers made from hub shells (a set of which I once owned, but foolishly sold in my youth). These days, coffee is the crossover world of choice, and Chris King has announced that it’s bringing back an old favorite.

The redesigned espresso tamper is similar to previous versions, but with a 15 mm-shorter handle that’s supposedly better suited for baristas.

“We recognize that a technique used by many exceptional baristas is using their fingertips to gauge the levelness of the tamper piston against the outer edge of the porta-filter and longer handles can get in the way,” said Chris King’s head coffee guru (and lead designer) Jay Sycip. “Making this change will allow for better more precise control for all baristas. It’s a small thing, but we felt it was important.”

Handle length aside, Chris King’s espresso tamper is a substantial hunk of metal, weighing in at 420 g with a standard 58 mm-diameter stainless steel base. The anodized aluminum handle is offered in nine different colors and fashioned to look like the company’s iconic threadless headset (sadly, they’re not actual headset parts; I checked).

Despite the US$150 asking price and only being recently released, the first batch is already sold out. Chris King has another run scheduled, though, so interested parties should probably make a point of getting themselves on the waiting list.

Old Man Mountain drops (some of) its prices

There’s some sort of universal law dictating that prices only ever go up, never down, right? Apparently, the folks at Old Man Mountain didn’t get that memo.

For those of you unfamiliar with the brand, Old Man Mountain specializes in heavy-duty cargo racks for stuff like bikepacking and commuting. Most of those racks attach to your bike via special thru-axles that have custom fittings on the ends for super secure installation even if your frame or fork doesn’t already have dedicated mounts (like nearly every full-suspension mountain bike).

Old Man Mountain refers to those thru-axles as “Fit Kits”, and thanks to a new CNC machine that was purchased late last year, the company says it now not only has an easier time keeping up with demand, but was able to reduce their manufacturing costs, too – and instead of pocketing the change, they decided to drop the retail prices instead. Fit Kits were once US$80 each, but now they’re US$68.

“We’re thrilled to be able to lower prices on our Fit Kits,” said Old Man Mountain marketing director Eric Fenner via press release. “In the rest of our lives we’re regularly experiencing rising prices and inflation, but as Old Man Mountain grows we are able to gain some manufacturing efficiencies. Part of the reason we love our axle mountable racks is because they make bikepacking accessible with whatever bike you have. Lowering the cost for a fit kit makes it 15% more accessible. Every bit helps.”

I’ll take it.

TrainerRoad links up with Zwift

If you prefer the structured training programs from TrainerRoad but also enjoy the video game-like virtual world of Zwift, you no longer have to choose between the two. You can now pull your TrainerRoad workouts directly into your Zwift environment, and the two companies have even made it exceedingly easy to do so: All you have to do is link your accounts.

From there, Zwift will automatically pull in whatever workouts you have scheduled in TrainerRoad, and then the self-adjusting resistance will do the rest.

Why can’t everything be this easy?

Philly Bike Expo is right around the corner

I’m not sure how I feel about adding more industry trade shows to the calendar, but I’m all in favor of more consumer-focused events like the Philly Bike Expo. After several years away, I’m looking forward to heading back to this year’s running, which will be held on the east coast of the United States in Philadelphia, Pennsylvania, March 8-9.

PBE is similar to other shows like Made in that it includes a mix of custom and mainstream bike brands, plus a variety of parts, accessory, and apparel companies. PBE is a fair bit smaller, but that also makes it a more intimate event with more time to linger and chat with various builders and brands (and more time for me to shoot pictures). PBE once again has a tasty-looking lineup of seminars on hand, too, including a deep dive on titanium with Brad Bingham of Bingham Built, an overview of wheel aerodynamics with custom builder Bill Mould, and even a discussion about training through menopause with legendary health and fitness journalist Selene Yeager of Hit Play Not Pause.

Another thing that has always impressed me about PBE and is the show organizer’s effort to make the event family-friendly. Kids actually get their own test track and skills course, an arts-and-crafts area, and lessons on basic bike maintenance, so mom and/or dad can spend a little more time checking stuff out. Kids under 12 get into the show for free, too.

Tickets are refreshingly affordable (just US$30 for two days), so if think you might be in the area, you can reserve your spots here.

TL;DR review: dD Rim-Tire Measure Tool

I can’t think of another time when riders have been so keenly aware of exactly how big a tire will fit in their bike. As such, I also can’t think of another time when riders have paid such close attention to how wide their tires actually are as compared to what they’re supposed to be.

It’d be straightforward enough to calculate the inflated width of a tire based on the actual width of the casing and the internal rim width if you paid attention in math class back in high school. But since most of us forgot long ago how to use π in anything, Wheel Fanatyk’s dD Rim-Tire Measure Tool does the thinking for you.

In the center of the tool is a gauge to measure the internal width of your rim, while on either of the rounded ends are scales to measure the casing. The tool was designed quite a long time ago, and so the two scales are intended for use with “road racing” or “mountain bike” tires. Gravel simply wasn’t a thing back then, but no matter; the tool still works as intended, even when it’s old and cracked like mine is.

Savvy readers will note there are no units printed on the dD, but no need to worry; that’s by design (feel free to dig into the math here if you’d like).

To use the tool, you hold the center scale up against your rim to collect the first number, and then you wrap the tire casing around either end of the tool to get the second number. Once you have those in hand, you just add the two numbers together to get a surprisingly accurate estimate in millimeters for the inflated tire width – no more guessing, no more hoping or praying, no more digging around on Internet forums. And I can assure that after having been using it for the last several years, it really does work well.

Granted, you do actually have to have the tire physically in hand, and the dD also doesn’t account for casing stretch over time (which is usually, but not always, pretty trivial). But if you’re particular about inflated tire width and are tired of rolling the dice, the dD provides a handy way to answer that question without having to mount the tire. In the event that number isn’t what you were hoping for (or what it’s supposed to be), this at least leaves you the option of returning it so you’re not stuck with something you don’t want or can’t use.

Given how expensive good tires are these days, that US$7 seems like money well spent to me.

Incoming: Eaglebear Black

Bike companies usually prefer to send flagship models for tech editors to review, for obvious reasons: they’re the nicest and fanciest, and most likely to yield the most glowing praise, price be damned. However, the reality is most of us aren’t spending that kind of money – often nowhere near it, in fact. Not only that, but those sorts of bikes aren’t even always many of us want or need on a day-to-day basis.

That’s why I’m quite excited about the Eaglebear Black.

Eaglebear is the adult-sized offshoot of kid bike specialist Prevelo, and the Black is intended to be an do-it-all model for people who just want to toss a leg over a bike and pedal. For lack of a better descriptor, it’s basically a modern-day hybrid in that the aluminum frame and carbon fork are built with a flat bar, moderately upright positioning, relatively high-volume 700c (or 650b!) wheels and tires, wide-range gearing, and lots of mounting points so users can customize their accessories as they see fit.

The Eaglebear Black isn’t cheap at US$1,300, but then again, it’s not really supposed to be. Instead, Eaglebear focused on high quality and long-term durability for the Black, and a quick look at the spec sheet reveals some smart choices like a Shimano Deore 6100 1x12 mechanical drivetrain, Shimano full-hydraulic disc brakes, and Kenda Alluvium Pro or Booster Pro tubeless-ready tires. The rest of the spec is largely no-name stuff, but based on prior conversations I’ve had with Prevelo’s gloriously nerdy product manager, I suspect they were chosen carefully.

The Eaglebear Black won’t make a ton of sense to enthusiasts, who just might not be drawn to the bike’s Jack-of-all-trades design. However, for folks who just want a “bike” – but a good-quality one – I’m curious to see how this will be received because heaven knows we could sure use more people riding bikes, period.

I’ve already got a test protocol in mind for this one, and you can rest assured it’s not going to involve a shred of Lycra.

ICYMI: Cannondale SuperX

Cannondale just brought back the SuperX model name, this time for a no-holds-barred gravel race bike that promises a silky-smooth ride, aero efficiency, and low weight. It also looks pretty fantastic in my opinion.

I don’t have one in my hands yet for a proper review, but even just looking at the specs (and after some back-and-forth with the Cannondale crew), I’m not sure I’m entirely convinced this is as cutting-edge as the aesthetics suggest it is.

You can find out why in my preview article here.

Tech tip of the week

I follow the social media accounts of quite a few experienced bike mechanics, who rarely fail to reveal some valuable nuggets of wisdom and knowledge. A recent one from UK-based mechanic Rich Steels at Detail Bike Tech was particularly good, and it reminded me of an incident I had myself several years ago.

I’d had a mysterious leak on a tubeless mountain bike wheel. There were no punctures in the tire, there was no air seeping out around the valve, and contrary to some other mystery leaks I’d dealt with in the past, the rim tape seemed fine. I chalked it up at the time to a particularly porous casing, and since I was perpetually strapped for time back then (as if that’s any different now), I would just chuck more sealant into it, pump it up, and call it good.

Lo and behold, I started snapping spoke nipples several months later, seemingly for no good reason. Granted, I built the wheels with alloy nipples, but they were ones I knew to be of very high quality. And while this was on a longer-travel trail bike, I’m generally pretty easy on wheels and I knew they weren’t needlessly abused.

A closer inspection of one of the failed nipples revealed that they were corroding from the inside out, and I immediately knew why.

As Steels’ post outlined, a mysterious tubeless leak can often indicate that your rim tape is no longer airtight. While it’s generally not a big deal if you have air slowly seeping into your rim cavity, that unfortunately also means you’re seeping sealant along with it (and let’s not even talk about carbon rims that absolutely, positively are not designed to stay together if the interior cavity becomes pressurized). If left unattended for too long, that sealant will eventually start to eat away at your spoke nipples, and given the immense tensions involved, they’ll inevitably start to crumble under the stress (quite literally, in this case).

“Before I began the rebuild I went around the wheel squeezing the spokes and managed to pop three nipples,” Steels told me. “It’s scary to think he thought the wheel was ok because it was running true, when under the surface it was a whole lot of wrong.”

The best thing to do if you’ve discovered you’re leaking sealant into the inside of your rim is to remove the old rim tape entirely and flush whatever goop that might be in there with fresh water. Once it’s completely dry (air guns are very helpful), thoroughly clean the outer wall of the rim, making sure to scrape off any dried bits of latex. Carefully install new rim tape and the valve stem, re-mount the tire with an appropriate amount of fresh sealant, and you should be good to go.

I know this sounds like a huge hassle – and it kind of is. But I can promise you that if you let the problem fester for too long, you’ll have a much bigger (and more expensive) fix on your hands later on.

Recipe of the week

We had some overly ripe bananas in the house a few days ago, so naturally that meant a loaf of banana bread was in order. I posted a pic of the end result on my Instagram page and received more than a few requests for the recipe, so here you go.

One of the things I love about banana bread (besides eating it, of course) is how it’s so tolerant of variations. A bit too much flour? A different ratio of sugar? Three small bananas or two big ones? None of it really matters; just mix it all up, pour it into a buttered loaf pan, chuck it into the oven, and you’ve got a lovely brick of deliciousness an hour later.

This one came to me from an old friend so it’s not only in imperial units, but also a little vague. No worries, though. Like I said, it’s hard to get it wrong.

Ingredients:

1 1/2 cups all-purpose flour (or 1 cup of flour plus 1/2 cup oats)

1 cup sugar (an even mix of brown and white, ideally))

2 or three very ripe bananas

1/4 cup oil or melted butter

1 egg (assuming you can find one!)

1 tsp baking soda

Vanilla extract (I go with about 1 tsp or so)

Cinnamon (um… some?)

Whatever else you want to toss in (my kid is partial to chocolate chips, naturally)

Mix it all up, bake in a buttered loaf pan for an hour at 350°F, and enjoy. That’s it!

Ok, that’ll do it for yet another n-1wsletter. Just a heads up that my kid will be out of school this coming Monday and Tuesday so I might not have a post up then, but we’ll see. Either way, I hope everyone enjoys their weekend!

I think I have +30g of dried sealant in my Enve 3.4 front rim. Noticed a bad tape job when switching out a tire with sealant leaking under the tape.

I weighted the wheel with no tape or valve and compared to the spec weight 😳 either it’s sealant or just variation in the spec weight. Even if so, I guess it’s in there for the rest of time.

James, just managed to find you here after

missing you over there. i’m really digging the recipes at the ends. it’s a neat surprise after carefully considering all the tech and introspection you curate, here.