There’s a huge range of helmets available on the market these days, comprising an incredibly broad assortment of features, weights, performance benefits, aesthetics, styles, and prices. Yet regardless of which make and model you prefer, there’s nearly a 100% chance that whichever one you’re using currently – and whatever helmets you’ve used in the past – was made with an expanded polystyrene (EPS) foam liner that was co-molded inside a thin polycarbonate shell.

Part of the reason for this commonality is that it just plain works.

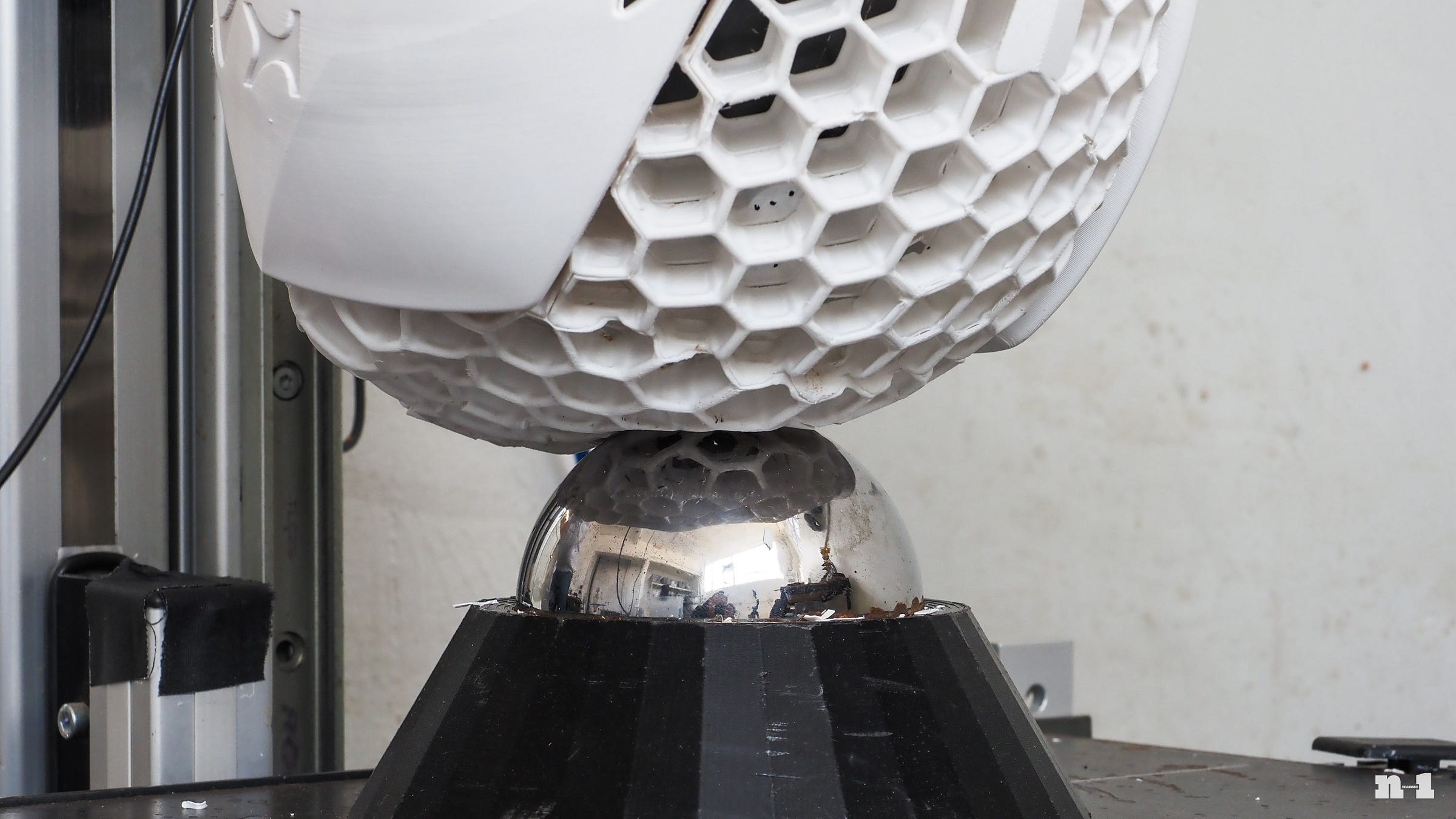

EPS is highly effective at absorbing impact energy, polycarbonate is lightweight and easy to form, and the combination affords all sorts of design flexibility. The technology is also highly evolved having been in use for more than forty years, so engineers are very familiar with how to work with the stuff. Even with newer liner materials coming on the scene in recent years like Koroyd and Wavecel, EPS is still the predominant material of choice.

Yet for as highly refined as this method of construction might be, is it the best way to make a helmet? Surely there are alternatives, no?

California-based brand KAV Sports would certainly like to think so seeing as how it’s built its entire existence on the concept of fully 3D-printed helmets. Its helmets use no traditional foams and no molding, and each is custom made to fit each individual rider’s head. KAV claims its 3D-printing technology not only makes for a safer helmet, but one that fits better with competitive weight and ventilation performance, and all without costing any more than comparable helmets made with more traditional methods.

I recently accepted the company’s invitation to come visit its facility in Redwood City to see what it’s been up to. Earlier KAV helmets I’ve tested in the past were certainly intriguing, but they still seemed like more of a novelty than a true competitor to the status quo. However, this fourth-generation model, the Rhoan, strikes me as a much stronger offering than anything KAV has offered before, and part of my goal with the trip was to learn more about it.

Arguably my larger aim was to dig deeper into KAV Sports itself: the people behind the brand, its 3D-printing technology, how its helmets are designed, why this method of helmet construction might offer some advantages over traditional EPS, and where KAV hopes to go from here.

To be clear, KAV did cover my travel expenses for this trip (including an unexpected night at a shady bargain-basement airport hotel I selected because I apparently can’t tell time). But there was otherwise no exchange of money, and this is most definitely not a sponsored podcast in any way: I asked the questions I wanted, I presented things the way I wanted, and the overall aim was definitely not for this to double as some sort of marketing fluff for the brand.

That said, I certainly learned an awful lot during the trip, and while I think KAV still has an uphill battle to fight before topping the helmet industry hegemony, the slope seems a little less steep than it once did.

Let me know what you think about this podcast episode in the comments below, and stay tuned for both my full review of the Rhoan as well as a much more in-depth factory tour article in the coming weeks.

Share this post