Canyon’s new MyCanyon custom program is more than just a fancy paint job (maybe)

The build-to-order purchasing process hints at bigger changes to come.

Canyon has long been one of the top go-to brands if you wanted a lot of bike for not a lot of money, typically undercutting its competition by hundreds – if not thousands – of dollars. Much of that savings comes from its consumer-direct business model, which allows folks like you and me to basically buy bikes at wholesale since there are no distributors or dealers.

However, another part of that savings comes from Canyon’s prix fixe catalog of offerings. While the German brand offers an awful lot of bike models, there’s always a very limited number of colors available, and none are offered with any level of personalization – until now.

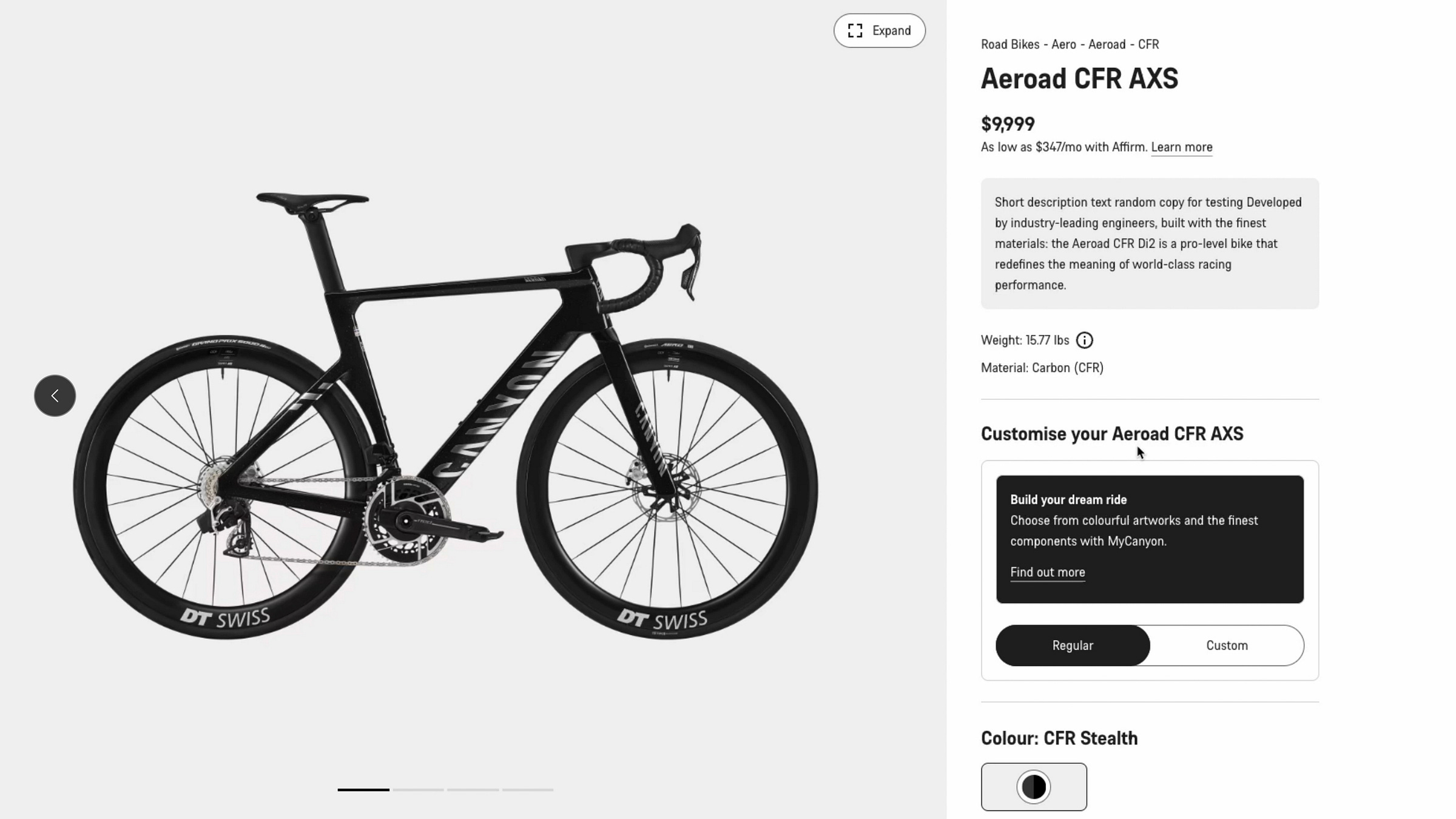

Canyon has just announced a new custom program called MyCanyon. It seems similar in aspiration to Trek’s Project One and Orbea’s MyO programs, though the initial reality is much more limited. For most customers, the biggest draw of MyCanyon will be the custom paint options, and even that should perhaps be more aptly described as semi-custom rather than a truly bespoke setup, or even the hundreds of permutations that Trek and Orbea offer.

At least for now, MyCanyon offers 13 pre-set schemes, split into three families, each with a very limited (if any) subset of options. And – again, at least for now – Canyon is only offering these optional paint finishes on its flagship Aeroad CFR aero road racing model.

The Fabrio paint collection includes three choices: Gold Dust (“A stunning golden yellow finish couples with striking mirrored decals”); Milky Way (“Painted using interference pigments, the frame looks like multiple colors at the same time”); and Dark Matter (“Representing the light and shade of the universe, this artwork combines a kaleidoscope of colors within a dark atmosphere”). Each Fabrio paint job will incur a US$500 premium over a standard Aeroad CFR.

Next up on the ladder is the more intricate Mano range, which includes four schemes (and two decal color options) to start, all of which are inspired by nebulae: Henize (“Finished with matte paint, Henize has a darker, meteor-inspired energy and a stone-like effect up close”); Leo (“Inspired by the magnificent Leo Nebula”); Carina (“Home to many massive stars, including many that are 100 times bigger than the sun, Carina glows bright and bold”); and Himiko (“Gaze into the majesty of the cosmos”). Canyon says all of the Mano finishes are completely painted by hand (does that mean the Fabrio ones aren’t?), and so these cost a bit more with an upcharge of US$700.

Canyon ramps things up with the Opus collection, with two designs that were developed with artists Felipe Pantone and Elena Salmistraro. Canyon says Pantone’s greyscale-and-iridescent geometric design is, “inspired by motion and technology,” and “riffs on the organized chaos of speed.” In contrast, Salmistraro’s design is far brighter and more animated, and “conjures the magic of color.”

Given all the layers and masking required for these two, Opus-level paint jobs will be the most expensive in the MyCanyon range by far, with additional charges of US$1,500.

More than just paint – but not much more

MyCanyon entails more than just a fancy paint job. There are also some customization options with sizing and componentry, although like with the finishes, the range of selection is “curated”.

Custom Aeroad CFR buyers will also have their choice between Shimano Dura-Ace Di2 and SRAM Red AXS electronic groupsets, DT Swiss ARC 1100 or Zipp 454 NSW aero carbon wheels (with Continental or Pirelli tires), and three different Selle Italia saddle models. You won’t be able to choose the size of that Selle Italia saddle, mind you, but Mano paint schemes will come with selectable colors for the Lizard Skins bar tape. And in a first for Canyon, you’ll also be able to choose your stem length from the factory, though in a restricted range from 10 mm shorter than stock to 20 mm longer (Canyon’s position is that if you need something beyond that, you’re probably buying the wrong frame size). Bar width is already adjustable, and customers can already choose between two different drop shapes.

As intriguing as MyCanyon sounds at first, careful readers will note that the program has some notable omissions.

There are no options in terms of crankarm length, for example, nor in gearing. And aside from the rather short list of component choices, you’re on your own, even with something as basic as seatpost head offset. Unfortunately, the MyCustom program is also only available for complete Aeroad CFRs at launch, meaning DIYers interested in custom painted framesets will have to go about that on their own.

“Our approach to customization is based on a combination of customer insights and delivering a well-defined scope to ensure the highest quality standards and a seamless customer experience,” explained Canyon’s global communications manager Ben Hillsdon. “Customer-centricity is at the heart of our program’s success; that’s why we've carefully selected component options for the launch that customers ask for most. That said, we are actively listening to our customers and will continue to refine the program based on their feedback. Crank length and seatpost variations are on our radar for future development.”

Whichever way you decide to go, Canyon is making it easy to go through all of the various options through a straightforward online portal. Weights, costs, and availability are updated instantly depending on your selections, though the former is based on a single frame size and average paint weights (paint can be surprisingly heavy, FYI, and there’s a 195 g swing from the lightest and heaviest finishes). Completed orders can also be tracked in relatively real time via a Canyon app.

“While the process itself is streamlined for ease of use, we are giving advice on the selectable options in every step of the configuration,” Hillsdon said. “We aim to offer customers an easy-to-understand experience – like in a boutique. We want to avoid an overwhelming burden-of-choice situation, where customers struggle with an excessive number of options, a challenge that is very evident among many competitor programs. Also, customers will have access to support from our customer service via chat, telephone, or in-person should they need assistance in making their selection. This approach ensures that every configuration maintains the high performance, quality, and design standards Canyon is known for. Our goal is to provide a balance between personalization and a seamless, confidence-inspiring experience.”

Canyon is quoting lead times of 6-12 weeks from when the order is finalized, with US-only availability to start (hence why I’ve only provided pricing in USD). The Asia-Pacific market is supposed to get access to MyCanyon by May, with the rest of the world being offered those same custom options around August. And again, MyCanyon is only being offered on the flagship Aeroad CFR model to start, although Canyon says there’s “more coming in 2026”.

Understandably, MyCanyon bikes won’t be treated to the same generous return policy given to in-line Canyon models. While they’ll be covered under the same warranty program, buyers will only have 24 hours after submitting their order to cancel. Delivery options include a box arriving on your doorstep, a more hands-on process with delivery and assembly courtesy of Velofix, and Canyon’s “New Bike Day” in-person pickup experience at the showroom.

Wider implications

I love a nice paint job as much as anyone, but it’d also be understandable if you’re feeling a little underwhelmed by what Canyon has rolled out here. The various finishes look enticing, but the component choices are very limited in terms of makes and models, and even the sizing options aren’t nearly as comprehensive as I’d prefer.

That said, keep in mind that Canyon is far from the curious little consumer-direct brand that many – Americans, in particular – perceived it maybe 10 or 15 years ago. Annual sales apparently haven’t quite hit the billion-dollar mark, but they’re well past the half-billion dollar figure, and the company operates multiple warehouses and distribution facilities worldwide.

As I mentioned initially in this article, Canyon’s business model to date has revolved around pre-configured complete bicycles. And so given Canyon’s scale, even offering a modest level of customization is a pretty big deal.

“This program does indeed represent a significant step for Canyon, not just in terms of offering customization but also in refining our logistical processes, especially in our Koblenz facility, which was built in 2015 with customization in mind,” Hillsdon told me. “Expanding to a customer-specific painting and assembly model is the logical consequence of Canyon being customer-direct and customer-centric. This initiative allows us to gather valuable insights into customer preferences, production efficiencies, and overall feasibility. As well as being a tremendous change for many of the background programs, systems, and supply chains, MyCanyon will also become a powerful learning machine to understand what customers truly need and prefer in terms of fit, function, and aesthetics. With this feedback, we will continuously refine and expand the MyCanyon program while also optimizing our inline portfolio to even better meet customer needs.”

Did you catch that tidbit about how MyCanyon will allow the company to “gather valuable insights into customer preferences, production efficiencies, and overall feasibility”?

Hillson obviously wouldn’t divulge as such, but reading the tea leaves a bit, it doesn’t seem like a huge stretch to see MyCanyon as a sort of pilot program for more widely available customization. Could Canyon potentially even switch to a true build-to-order model company-wide? Might it perhaps even ditch pre-set models entirely in favor of a system where it keeps in inventory bare framesets and parts, and then assembles each bike from there? Just something like more widely available customizable component sizing could be massively impactful, particularly on bikes with more convoluted fully internal cable routing and integrated cockpits where even a 10 mm change in stem length can easily carry a US$350 price tag above and beyond the purchase price of the bike.

I would imagine doing such a thing top-to-bottom on a company of Canyon’s scale might be an unrealistically heavy lift, but I do know of at least one decent-sized brand that’s been successfully doing just that for years.

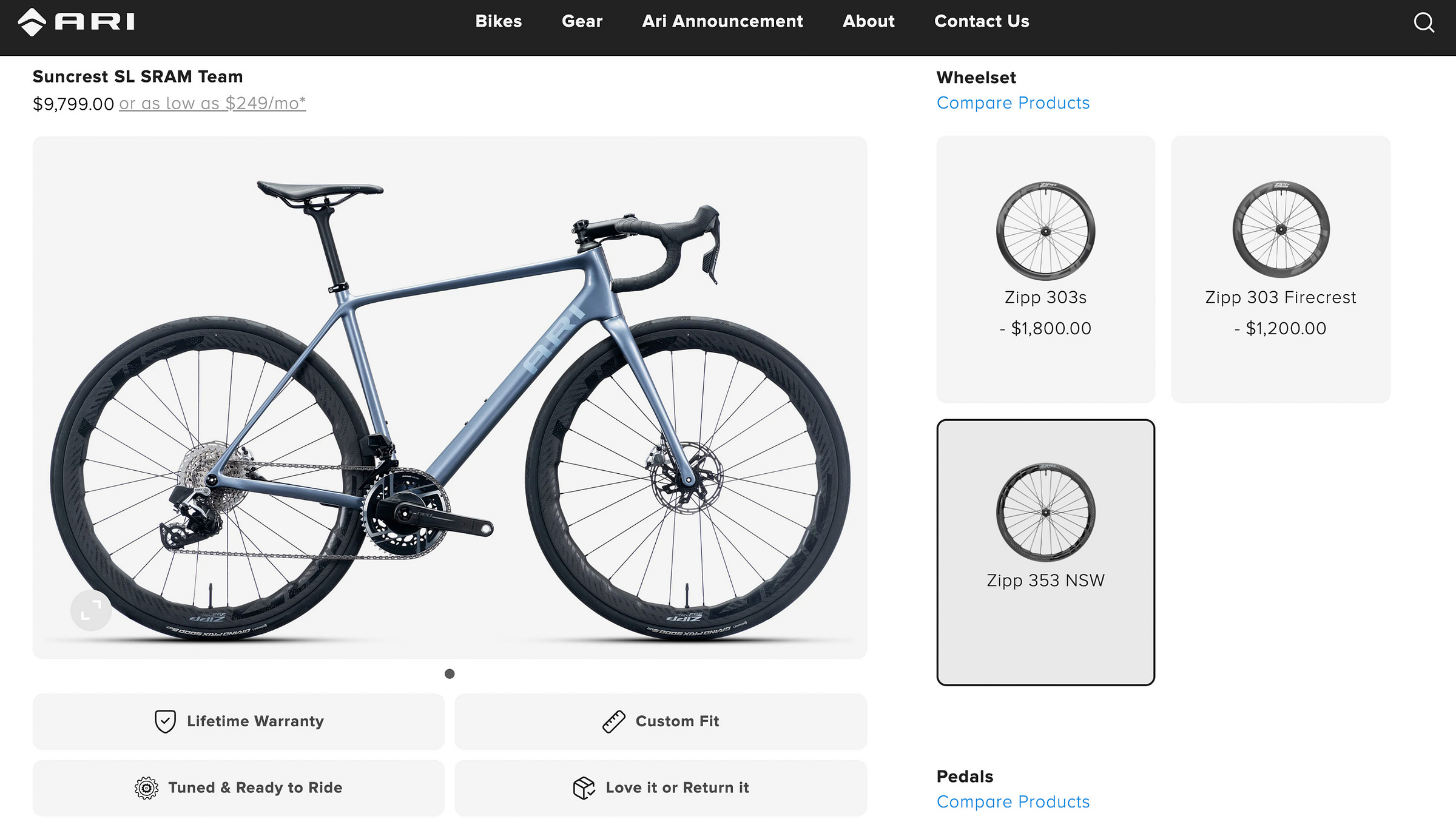

Ari Bikes (formerly Fezzari) doesn’t assemble pre-configured bikes that are sealed in boxes until someone buys one. It keeps bare framesets in inventory, along with a wide range of groupsets, wheelsets, and ancillary parts, most of which can be mixed and matched by the customer during the ordering process. Want a top-tier frame with a more basic groupset? Or a less expensive bike with more premium wheels? Need a longer or shorter dropper post, or have your own preference with tires? Done, done, done, and done.

“[Build-to-order] allows us to get customers the exact bike they are looking for,” said Ari Bikes’ director of product development and marketing, Tyler Cloward. “The advantage is in the customer’s favor for building their dream bike and getting it how they’d like it and not having to do some small parts swaps after they get the bikes.”

Cloward says that operating on a build-to-order helps with cash flow, too, particularly at the high end.

“One advantage is on the very expensive parts. We can plan these parts so they work across multiple frame offerings. Instead of an expensive Red or Dura-Ace, or XX or XTR kit preassembled on each of the frame offerings, we can bring in 20-30 kits at a time and move those across the different frames. If we were to do the full pre-assembled route we could be sitting on hundreds of bikes and millions of dollars once we add all the frame platforms, sizes and colors, etc. to be sure we can offer the correct frame, color, and size to the customer. We may have to stock the frames to meet this demand, but it reduces the component costs and helps manage inventory and cash.”

This all sounds good in theory, of course, but Ari Bikes is a fraction of the size of Canyon – and while the company has more global aspirations, Ari currently sells primarily within North America. Could that sort of model even be adapted to a company the size of Canyon?

“Scalability is a challenge for sure,” Cloward admitted. "If it was easy, everyone would be doing it. While I can’t speak to what other brands are doing or how they may go about things, we have been successful at scaling the customization portion of our offerings. We have been able to utilize nearly two decades of data we have from customizing so many bikes. We use this to better forecast what the customization we may see. We have worked really hard with our supplier partners to be up on new trends and upcoming products. We also regularly communicate with current and potential customers at demo events, festivals, races, group rides, etc., about their preferences and work to adjust offerings based on customer needs.

“A big challenge is customer communication. How do you stay up on the back-and-forth communication with potential buyers while also staying efficient in that? That is a really hard one. We are constantly updating things here.”

Certainly there are a lot of benefits to Ari’s build-to-order business model from a customer perspective in that it offers a much broader range of options than pre-configured bikes. Whether Canyon is actually considering a similar a move company-wide is still to be determined, but the idea of it certainly gets my gears spinning – and if competing companies aren’t worried just at the thought of this happening for real, I think they should be.

Remember how back in the day, folks interested in a more premium aluminum Cannondale road bike would buy a lesser complete model, sell off the cheaper bits, and then rebuild it with nicer stuff? How awesome would it be to just spec it like that straight from the factory? Canyon has already been widely regarded as an industry “disruptor” for its hyper-aggressive retail prices. How disruptive would it be if the company could offer a semi-custom experience while still keeping prices in check?

I certainly don’t have the answer to that question – but I sure am curious to see how such a thing might shake out.

Just a heads up: This post took up a fair bit of time, so there will unfortunately be no newsletter this week. I should be back on the normal schedule next week. Have a great weekend!

Good moves by Canyon, but still work to do I think. I bought my last road bike from Factor, and their customization was a BIG draw, as well as the bike fitting from ACME bikes in NY. I was able to chose my own wheels, crank length, seat post set back, stem length, bar width…. While the bike was not cheap, it fits like a glove :-)

That quote from the Canyon PR guy sounds like his budget only allows for the free version of ChatGTP.