KAV Rhoan helmet review: Hitting the 3D-printed inflection point

It’s not quite perfect, but it’s awfully close

KAV Sports has been at the custom 3D-printed bicycle helmet game for almost eight years now, and oh-how-far the company has come since those early days. The idea of printing a helmet may have seemed like mostly a novelty back then, and indeed, earlier models I’ve tested over the years were middling at best. However, KAV’s fourth-generation helmet, the Rhoan, is finally living up to those heady promises, and the technology behind it also portends a lot more potential for even more significant performance gains moving forward.

If you’ve been standing on the sidelines watching with curiosity the storyline of 3D-printed helmets, now might be a good time to get yourself into the game. The Rhoan isn’t merely a good helmet; it’s legitimately excellent.

A no-show to the foam party

It’s hard to understate just how unusual it is to produce a bicycle helmet using 3D-printing. At the time of this writing, Virginia Tech's independent test lab has evaluated 277 bicycle helmets in total, and all but two feature some level of traditionally molded construction – and mostly with expanded polystyrene (EPS) foam liners combined with some type of plastic shell.

The bike industry has settled on this configuration for a variety of reasons. EPS is generally very good at absorbing impact energy, it’s lightweight, and it’s available in a wide selection of formulations, and when paired with a thin plastic (usually polycarbonate) shell, the combination affords an incredibly broad range of design flexibility in terms of both cost and performance.

With roughly four decades of experience with the technology, the industry has also gotten extraordinarily good at it. By and large, the general consensus at this point is that this is just how it’s done, and most people have been satisfied with leaving it at that.

As with most materials designed for the purpose, EPS foams absorb energy through deformation, and while helmet designers can choose various densities and thicknesses of EPS to yield the desired performance traits, it’s still basically an isotropic material. In other words, if you were to take a cube of the stuff and smash it with a hammer, it’d absorb impact energy the same way no matter how you oriented it on the bench top. Moreover, there are limits to how much the foam can be compressed before it’s no longer able to absorb energy.

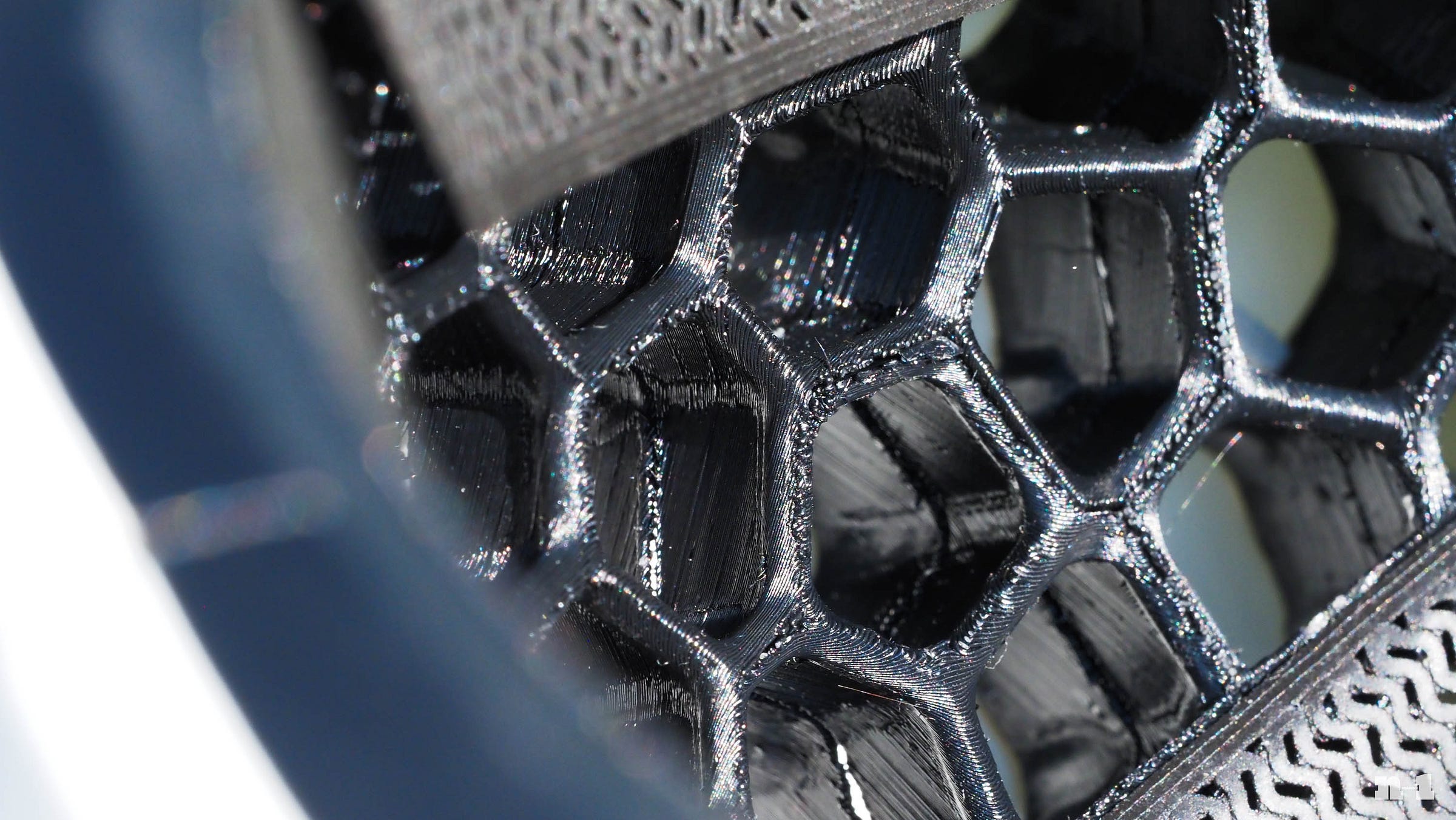

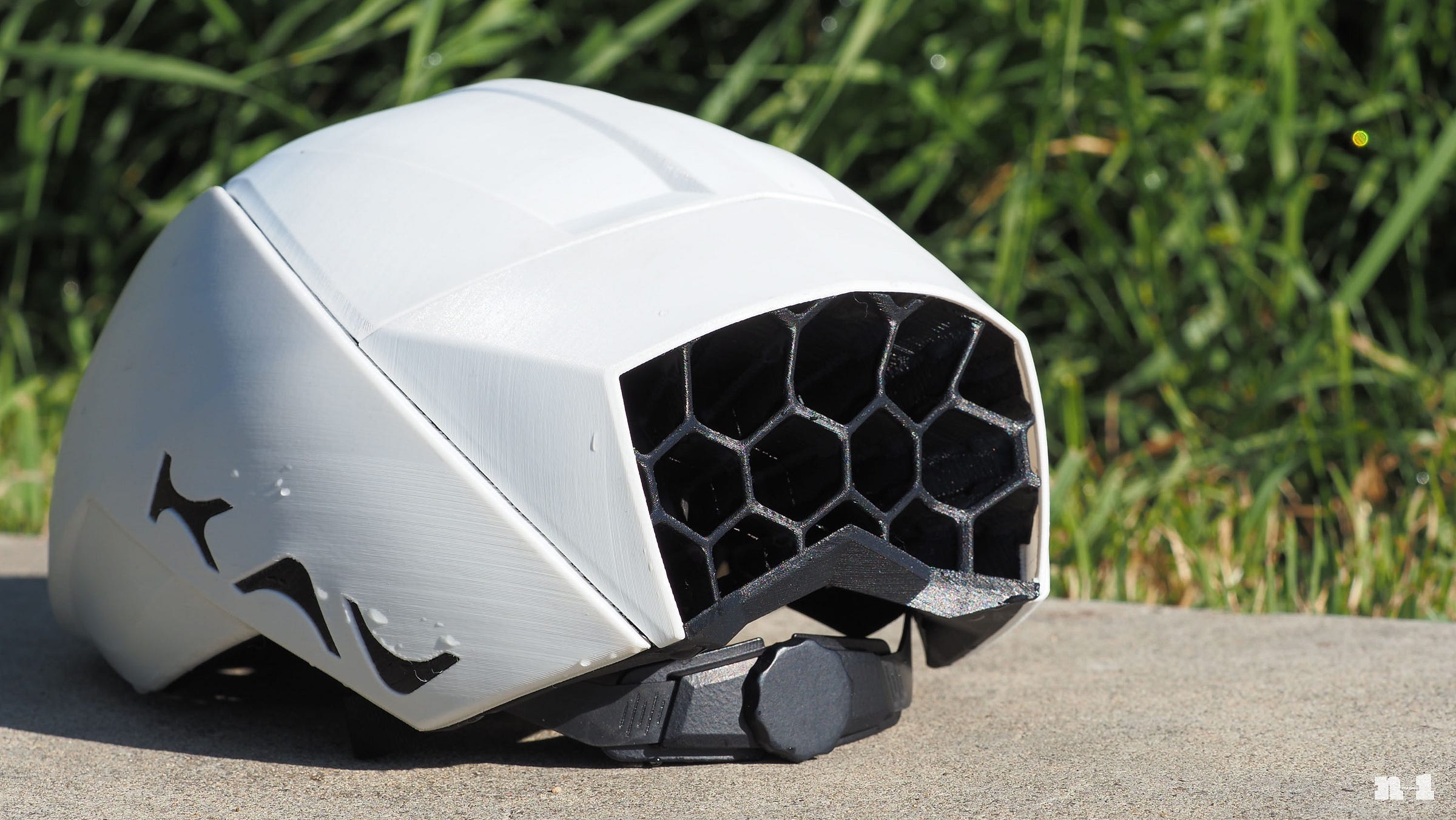

KAV instead uses a 3D-printed honeycomb-like cellular structure that’s intended to behave more like the crumple zones in a modern automobile – sort of like what happens to an empty beer or soda can when you step on it. According to KAV Sports co-founder and CEO Whitman Kwok, these structures are just a lot more efficient weight-wise than EPS in terms of the amount of energy that can be absorbed.

“EPS foams hit a point of densification on compression at which point it no longer absorbs energy and passes impact forces directly to the head,” Kwok explained. “For the higher density foams typically found in helmets with a lot of vents or aero helmets that are slimmer, this densification or lock-up occurs about a third of the way through compressing. Put another way, it’s as if your suspension fork locks up a third of the way through the travel. So even if your helmet is 30 mm-thick (picking nice round numbers), you only get 10 mm of cushioning. With our hex structure, it can crumple almost through the entire offset thereby giving three times the energy absorption – 30 mm of travel with 30 mm of offset.”

To be clear, KAV isn’t the first company to propose using a cellular-type crash structure for a bicycle helmet. The Smith Optics Forefront helmet introduced Koroyd to the mountain bike world in 2013, with its trademark neon green tubular polycarbonate liner material resembling an array of fancy drinking straws glued together. Six years later, Bontrager introduced a different cellular technology into its helmets called WaveCel, which instead featured wavy polycarbonate sheets that were layered on top of each other.

Although both Koroyd and WaveCel adopted a crumple-zone philosophy like KAV, there are some big differences. Koroyd and WaveCel both use uniformly extruded and bonded polymer structures with the same cell wall thicknesses, material densities, and cell geometries throughout the liner. It’s also worth noting that neither is used in bicycle helmets exclusively; instead, both are supplemented with traditional EPS foam and still feature traditional molded polycarbonate shells.

Because KAV is 3D-printing everything, it can locally adjust the diameter, height, shape, and densities of the cells in different areas of the helmet depending on the desired characteristics. KAV also adds hollow tubular structures to the edges of the cells – sort of like how new parents add foam padding to coffee tables – that not only provide another crumple mechanism to absorb crash energy, but offer more gently rounded edges against the head.

Wondering about rotational forces and oblique impacts, and their effect on traumatic brain injuries like concussions? It’s certainly a hot-button topic these days when it comes to bicycle helmet safety, but if you’re looking for a MIPS logo on a KAV helmet, you won’t find one. Instead, KAV has come up with its own solution, integrating a low-strength shear layer directly into the cellular network. This supposedly creates a sort of ball-and-socket, helmet-within-a-helmet structure to deal with rotational impact forces. This is analogous to MIPS Spherical in concept, although instead of allowing free rotation all the time, KAV’s approach only allows those two layers to separate in a crash.

This all sounds well and good from a technology standpoint, but KAV’s real ace in the hole is arguably its manufacturing methods. Traditional helmets are made in bulk quantities, with hundreds – even thousands – of identical helmets coming off of various assembly lines and with hundreds of thousands of dollars in tooling costs to match. Such processes are what allows lower-cost helmets to exist, but KAV argues that it also limits what can be done on higher-end ones.

3D FTW

In sharp contrast to how things are usually done in the bike helmet industry, there’s no tooling at all inside KAV’s facility in Redwood City, California. The production area is filled with almost nothing but three-tiered racks of readily available 3D printers, and each helmet is custom designed and built to order instead of being offered in typical T-shirt sizing with fixed colors and styles.

KAV once required prospective buyers to provide an array of physical measurements, which was not only cumbersome, but prone to user error. The new process is laughably simple in comparison, and requires nothing but a single smartphone selfie (sorry, iPhones only) and a physical circumference measurement to produce a three-dimensional representation of your head. KAV then uses that information (along with some one-on-one discussion if there are special circumstances involved) to craft the helmet shape, promising a 3D-printed helmet that not only fits perfectly right out of the box, but also provides the same levels of safety regardless of head size or shape.

Ever found yourself needing a helmet that was just a little more ovoid inside? Is your current helmet spot-on with the exception of perhaps a couple of pressure points at your temples? Did your parents leave you on your back too long as a baby and you’ve got a funky flat spot on the back of your head? All of those are supposedly easy problems to solve, and KAV even offers nine different shell colors and two colors for the cellular liner.

Savvy readers may be feeling a bit of déjà vu here.

British outfit Hexr made similar claims when it first hit the market with its custom 3D-printed helmets back in 2019. However, Hexr only tweaked the inner layer of its cellular liner to suit the rider’s particular head. The shape of the outer layer was fixed and offered in six discrete sizes, with a molded polycarbonate shell to match. KAV’s process is more flexible in terms of size and shape since it’s 3D-printing the entire structure, not only including the liner and outer shell, but also the strap sliders, adjustable retention system, and even the padding. The only bits purchased from third-party vendors are the buckles, the webbing, the stainless steel pins used to secure the webbing in the liner, and the screw that holds the retention system together.

And unlike Hexr – whose public-facing presence has been quiet since 2022 – KAV is still selling helmets to people.

KAV has essentially operated as a startup for much of its short existence, and it’s really only offered a single helmet model at any given moment in time. That said, it’s already gone through three generations of helmets since 2021, and it’s now rolled all of its learnings into a new fourth-generation helmet called the Rhoan.

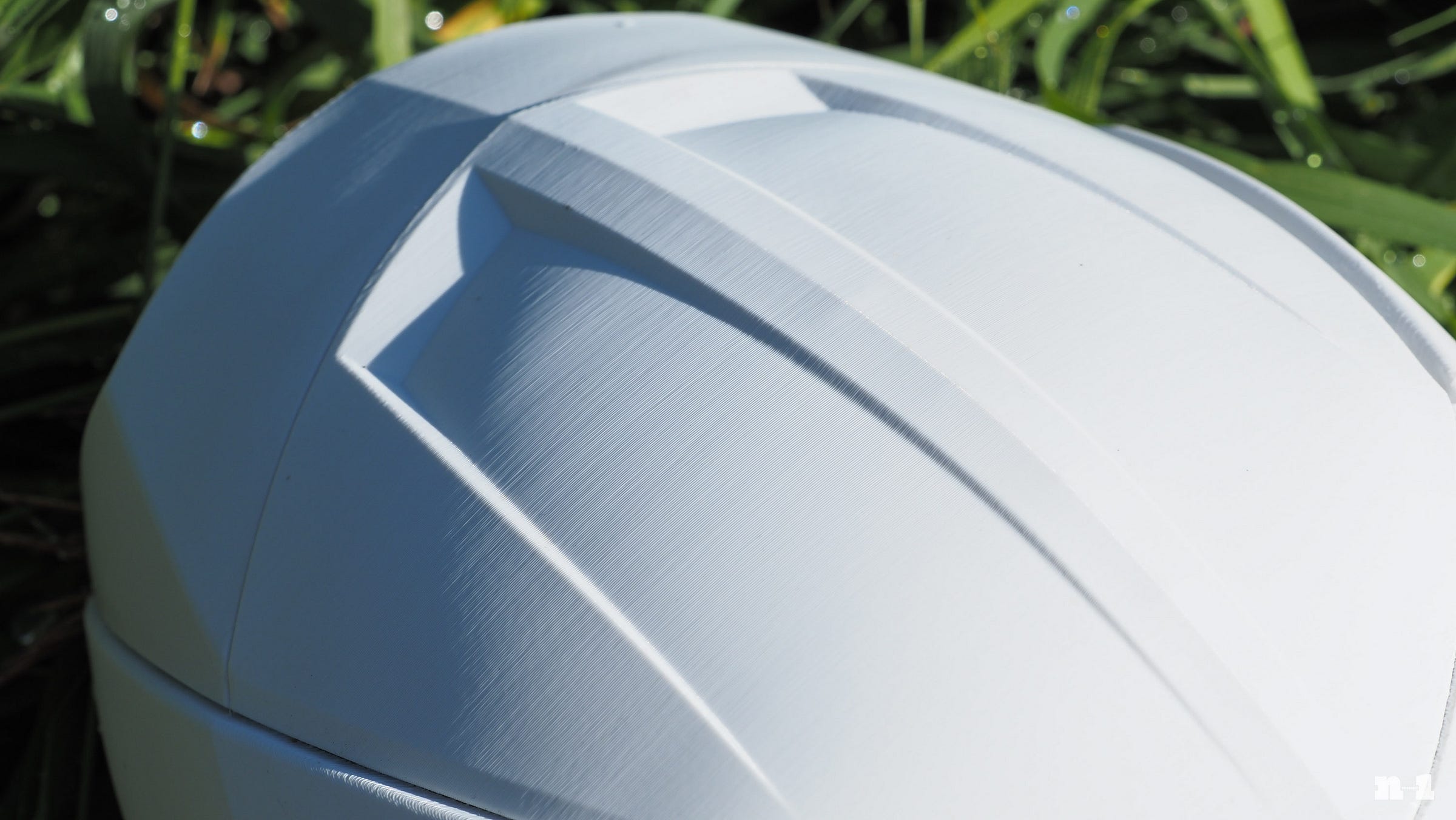

KAV’s earlier helmets were designed as more all-around lids, but the new Rhoan is intended to be a proper aero road model that the company says goes toe-to-toe in the wind tunnel with big-name competition, in particular the Specialized S-Works Evade 3. KAV also says the Rhoan is about 20% lighter than its previous Nova model, substantially cooler in terms of ventilation (despite being more aerodynamic), and about 6 mm lower-profile on average for a more tucked-in look.

Retail price for the new Rhoan is US$300. It’s unfortunately only sold in the US at the moment pending additional certifications, but it includes a five-year warranty and a one-time free crash replacement should you smash your noggin into something during that period (while wearing the helmet, presumably). Actual weight for my roughly small/medium-sized sample is 327 g.

Fourth time’s the charm?

As I mentioned at the beginning of this article, I’ve tested a couple of KAV’s earlier 3D-printed helmets and I wasn’t exactly blown away. Whether in fit and finish, ventilation, weight, sweat management, aesthetics, or something else, they just always felt like they weren’t quite fully baked.

This new Rhoan, on the other hand, is a giant step forward. It’s not without a few remaining quirks, but by and large, I’d consider it to be a proper competitor in the category.

First off, the quality of fit is superb, which is mighty impressive given how little information KAV asks of you. In fact, I actually went through its fit process twice thinking I’d missed some steps. After all, how on earth could anyone determine the shape of my head using just a single frontal image and a physical circumference measurement? KAV says it’s able to correlate your facial features to the shape of your skull, and regardless of how unbelievable that seems, it somehow works (at least for me).

Further advancing the cause are KAV’s new Air Fit pads (which, again, are printed in-house). These aren’t like other helmet pads you’ve seen, which typically use some sort of low-density foam sandwiched between two layers of fabric. Instead, the Air Fit pads are almost like little hammocks that gently suspend the interior of the liner a few millimeters off of your scalp. I’ve often described well-fitting helmets as being akin to wearing a winter cap, but between the astonishingly accurate shape of the Rhoan and those clever Air Fit pads, the Rhoan doesn’t feel like it’s hugging your head so much as it’s floating around it.

The dial-type adjustable rear cradle is also designed and printed in-house. I was initially disappointed that it’s not adjustable for height, but the helmet itself fits so well that I honestly don’t find the cradle necessary at all. As it turns out, KAV designed the cradle to be easily removable to prevent damage while traveling, but I eventually just pulled it off and never put it back on, and I haven’t looked back since. For reference, the last time I ran a helmet without any sort of rear retention system was the early 1990s.

Speaking of hats, earlier KAV helmets didn’t leave enough room for an extra layer when the weather turned cold. Granted, it hasn’t exactly been chilly since I started using my test sample in early April, but I’ve walked around my house with a winter cycling cap under the Rhoan enough at this point to confirm there’s not only sufficient space, but that it still fits just as well as without it.

And let’s talk safety, eh? The Rhoan has not only managed the coveted five-star rating from Virginia, but it’s also the ninth-best road helmet in Virginia Tech’s database overall – well ahead of the Evade 3, the Giro Eclipse Spherical, and the Trek Ballista MIPS, all of which only managed a four-star grade.

Ventilation has been another high point.

Helmets with cellular-type crash structures have often been somewhat contradictory to me on this front. On the one hand, accumulated heat can readily escape because the materials don’t insulate like EPS foam, which I’ve found can sometimes make the helmets feel uncomfortably cold in even moderately chilly conditions. But on the other hand, because they also generally lack the deep internal channeling of traditional helmets, flow-through ventilation is often pretty poor so you don’t get much of a cooling effect when you’re moving.

The Rhoan thankfully manages to strike a surprisingly good balance.

KAV equips the Rhoan with a large U-shaped opening up front and a similarly large rectangular exhaust port out back. There isn’t any internal channeling in between, though, so you wouldn’t expect that there’d be much air movement between the two. Even so, there’s a remarkable amount of flow across the top of your head when you’re moving along. Remember that hammock-like Air Fit padding? Because it suspends the entire helmet off the top of your head, it allows air to circulate throughout the entire interior so air can not only get in, but also get out. It doesn’t always feel as effective as traditional channeling, but it’s effective nonetheless.

That said, let’s not forget that KAV designed the Rhoan as an aero road helmet so low-speed ventilation still leaves plenty of room for improvement. It’s better than expected – presumably because the honeycomb structure just doesn’t hold heat like EPS foam – but this definitely wouldn’t be my first pick for a long day of climbing in midsummer heat and humidity.

I guess this would be a good place to start mentioning negatives because another notable weak point is sweat management. Whereas most of the Rhoan’s padding features an open mesh structure to facilitate airflow, the browpad is nearly solid, with only the tiniest holes that KAV contends are small enough to keep sweat from passing through but still allow some airflow. The idea is that it’s a built-in gutter of sorts (not unlike the actual Sweat Gutr, which I’ve successfully used for years), channeling sweat out to the sides and/or out through the forwardmost air vent.

The problem is it doesn’t work.

Those holes are roughly the same size as what you’d find in a typical portafilter, and as any coffee aficionado could tell you, it’s pretty easy for water to flow through. It unfortunately doesn’t take long at all for sweat to dribble down your face (and into your sunglasses) when wearing the Rhoan, to the point where I rarely left the house with also donning some kind of headband. Making matters worse, the edge of the pad consistently leaves an annoying line in my forehead that admittedly isn’t uncomfortable, but is annoying nonetheless.

KAV is aware of both issues and is apparently considering retrofittable running changes, but we’ll see what turns up.

“Thanks to our local production, we can incorporate feedback and keep fine-tuning our helmets for our riders,” Kwok told me. “Like training, product development is a continuous process.”

KAV has managed to bring the weight of its helmets down over the years, but even so, the Rhoan isn’t all that light for a top-end lid. It’s about 50 g heavier than the Specialized S-Works Evade 3 or Trek Ballista MIPS, for example, and Giro has even managed to keep the weight of its Eclipse Spherical aero helmet inline with those mainstream competitors despite its complex dual-layer construction. Ditching the Rhoan’s retention cradle narrows the gap a bit, but many riders won’t want to do that.

KAV has improved the general robustness of its helmets over the years, and the Rhoan comes across as feeling reassuringly stout despite basically being made of plastic thread. It’s held up well to day-to-day use and abuse, and it’s super easy to clean, too. Three months on, it still looks as good as new.

Even so, it’s impossible to overlook how the Rhoan is made. The print grain is impressively fine but still clearly visible, the seams in the multi-piece shell are more pronounced than what you’d find in molded polycarbonate, and there are a few spots on my sample that don’t seem as smooth as they should be – not so much that I worry about them, but my suspicion is that people paying US$300 for a bike helmet might not be overly thrilled with the finish quality.

I’d argue the styling in general is rather polarizing, too. I was a massive fan in my youth of Japanese anime cartoons like Robotech, Macross, and Gundam, and my guess is that whoever penned the Rhoan’s aesthetics likely had a similar upbringing. Nevertheless, the angular aesthetic is a sharp departure from the more organic shapes you often find elsewhere, and it just doesn’t strike me as being as refined as the competition.

KAV may have figured out a workaround to traditional internal channeling in terms of ventilation, but for riders living in buggy climates, that also means any stinging insects that find their way into the forward vents are likely to stay there instead of getting flushed out the back. The built-in sunglass stash ports work great, though.

Last complaints? The chinstrap is a bit shorter than I’d prefer, and while the 3D-printed sliders are neat, I wish they locked in place a little better. I find the big “KAV” logo on the left side of the helmet to be a bit tacky (the one on the right side is thankfully smaller). And this is more of a quirk than a complaint, but the helmet’s hollow construction is awfully loud if you find yourself caught out in a rainstorm.

Tailwinds at last

It’s been fascinating to watch KAV’s progression over time. What initially seemed like a novelty has now evolved into a legitimate contender, and while there are still some downsides, I no longer have any qualms about considering the Rhoan to be on equal footing with its more conventional competition.

It scores great in independent safety tests, it’s impressively aero (if you take KAV’s data at face value, that is), it’s remarkably comfortable, it’s very well ventilated (for the category), and it includes custom fit and color possibilities that aren’t even available elsewhere despite being competitively priced.

Sure, one might argue that KAV’s helmet is still a little weird, but you can no longer say it isn’t as good as the competition and I’m eager to see where KAV takes things from here. Maybe swappable vent plugs for all-weather customization? Interchangeable shell panels to match your kit? Perhaps a lightweight climbing model or even an expansion into MTB?

Keep on keepin’ on, KAV. I’m liking what I’m seeing here.

I am very much sold on the custom fit, especially after listening to your podcast interview the other week. I'm hoping they add some additional colors to match team kits...

What would be your pick for a very hot and humid climate?