Argonaut Supernaut GR3 gravel bike review: Crazy expensive, but also crazy good

No joke: it’s the finest-riding gravel bike I’ve ever had the pleasure to throw a leg over.

What makes a bike good? What makes a bike great? What makes a bike truly superb? Bike performance can sometimes be boiled down to a set of test bench numbers. But sometimes, it’s just a feeling, and when all the stars align, that feeling may as well be magic.

I’m not sure what kind of deal with the devil Argonaut founder Ben Farver made to produce the otherworldly ride quality of his Supernaut GR3 carbon fiber gravel bike, but I sure hope he’s got a comfy chair waiting for him down there.

Because wow, has this thing blown my mind.

Pros: Electric ride quality, insanely comfortable, ultra-lively, pseudo-progressive handling, excellent tire clearance, elegant aesthetics, built-in exclusivity.

Cons: Super expensive, limited customization options, fully internal cable routing, no internal storage, potential for mud build-up, wheel flop.

The takeaway: When I win the lottery…

Going its own way

Argonaut occupies a prominent position in the high-end carbon drop-bar space these days, but if you haven’t heard of the brand, that’s not entirely surprising as the company only produces about 160 bikes per year and doesn’t exactly have a massive marketing budget. Chances are even lower that you’ve ever even seen one.

Farver founded Argonaut in 2007, but his focus at the time was on custom steel bikes since that’s what he preferred to ride himself. As much as steel has going for it as a frame material, though, math is still math. The sad reality is that it’s not only heavier than the usual non-ferrous alternatives, but its anisotropic nature also means there’s only so much you can do with it in terms of tuning its performance. And from a business standpoint, as proud as Farver was of the frames he was producing, he quickly came to the realization that it was tough to stand out when there were already so many other accomplished builders with longer track records and better name recognition.

Farver made a dramatic turn in 2010, switching from steel to carbon fiber, with the idea that Argonaut could produce composite frames with the ferrous-like ride quality he’d always prized, but much lighter and with a broader range of performance customization.

“One of the reasons I decided to switch from making steel bikes was that I felt like it was really difficult to differentiate and elevate the frames I was making in relation to my peers,” he told me. “My Columbus Life steel frame was basically identical to a Pereira or Ira Ryan, etc. underneath the paint – and often we were using the same painter!”

That theme of differentiation went further than just switching materials. One of the most common production processes for custom carbon builders is tube-to-tube, where finished carbon tubes are mitered, bonded, and then over-wrapped with additional plies of pre-preg – a composite analog of TIG-welding in some ways. Smaller outfits often prefer tube-to-tube because it requires less tooling than the bladder molded constructions that big brands tend to favor, and it can certainly make for a fantastic bicycle (see Crumpton, Calfee, Parlee, Appleman, and so on). But for Farver, going that route would only put him back in the same dilemma, only now in carbon fiber instead of steel.

“A custom or handmade steel frame back in 2010 was definitively better than one welded by robots overseas,” Farver said. “That wasn’t necessarily the case in carbon. A bike I could make out of mitered and bonded carbon tubes wasn’t necessarily better than top shelf production carbon, and I didn’t want to switch from making the best version of something to making something that didn’t measure up from an engineering standpoint. I saw doing custom, bladder molded carbon as an opportunity to bring something new and better to the industry.”

Farver initially used metal clamshell molds pressurized from the inside with latex bladders – all done practically down the street at Innovative Composite Engineering in White Salmon, Washington – but with an adjustable design that allowed for custom geometry.

“We could pull a full customizable size range out of one set of tools, but more importantly we could customize the lay-up pattern also, dramatically affecting how the bike rode. Innovative Composites made the frame sections for me based on specified angles and lay-up patterns, and I fabricated and finished the frame in my shop in Portland.”

Farver brought everything in-house in 2018, and things have certainly gotten more interesting since then.

Argonaut still uses a modular-style frame layout with nearly a dozen separate components, but it no longer uses inflatable latex bladders to apply pressure from inside. Instead, individual pre-preg carbon plies are wrapped around semi-rigid silicone rubber pre-forms, and then that sub-assembly goes inside a clamshell mold. When heated inside the curing oven, the silicone material expands more than the aluminum clamshell, which Argonaut says compresses the carbon plies to around 600 psi – or almost three times what’s typically used in more conventional pneumatic methods.

That super-high internal pressure supposedly not only squeezes out more excess resin than usual, but it also makes it less likely that any residual porosities will be left behind, both of which theoretically make for a lighter part with fewer voids.

Because the silicone pre-forms, the molds used to make those pre-forms, and the aluminum clamshells are all made in-house, Argonaut says it can produce a wide range of custom geometry while still offering the structural advantages of a modular monocoque frame. Moreover, tube sections are made in a range of lay-up patterns that allow for tunable stiffness profiles, and the combination yields a broad range of ride qualities to accommodate different rider weights, power outputs, and preferences.

If all of this sounds expensive, well, it sure is.

Reimagining “stock”

Argonaut currently only has four bikes in its entire catalog: the RM3 custom road bike, the GR3 custom gravel bike, and then the so-called Supernaut versions of each.

The custom models are just about what you’d hope they’d be from a top-tier, no-holds-barred bespoke brand like Argonaut: custom geometry, personalized lay-up, custom parts build, custom paint. Basically, just about anything within reason that you want or can dream up – and are willing to pay for – is available. According to Farver, a typical full-custom complete RM3 or GR3 goes out the door for around US$19,500.

Yowza.

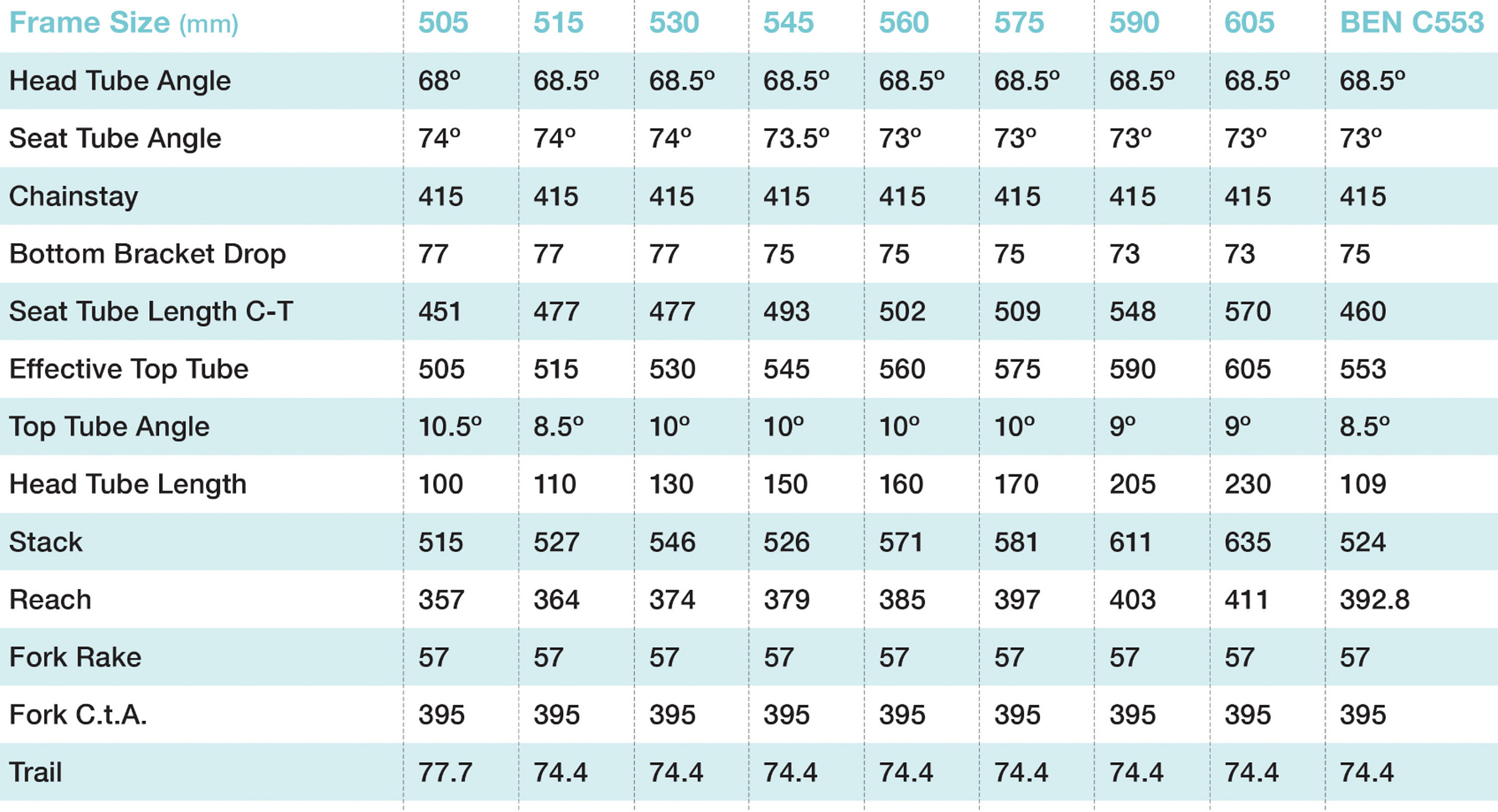

On the other hand, Argonaut’s newer Supernaut range is designed to be more accessible, though still at the ultra-premium end with a retail price starting at US$15,900. Argonaut says the cost savings don’t come through things like lesser materials or processes. Supernauts are manufactured exactly the same way as the full-custom models with the same “high pressure silicone molding” methods and identical materials, but with eight pre-set frame geometries (nine if you count Ben’s personal “BEN C553” extra-long-and-low setup, which is also available), pre-set size-specific tube lay-ups, a single paint scheme, and pre-configured premium build kits, there’s an awful lot less time and communication required to get an order finalized.

After all, as the saying goes, time is money.

According to Farver, the Supernaut is a “distillation” that combines the company’s experience with fully custom builds together with his and his employees’ own preferences.

“The Supernaut is essentially the solution for someone who walks into our shop and says, ‘I don’t need anything custom; just build me your best bike.’”

Buyers still get some choice in component sizes, such as stem length, headset spacer stack, bar width, crank length, and seatpost setback, and there are a few choices of tires, too. There are a small handful of available upgrades, too, such as an Enve one-piece cockpit, a CeramicSpeed oversized pulley wheel derailleur cage assembly, and on the Supernaut GR3 gravel bike, a dual-sided power meter (Supernaut RM3s come with one already). Farver says they can also provide other bits that aren’t on the menu at all, like pedals, computers, or “whatever else the customer needs.”

By and large, though, the Supernaut is intentionally prix fixe.

On the Supernaut GR3 gravel model I’m reviewing here, the build kit includes a SRAM Red AXS XPLR 1x13 wireless electronic groupset (a Shimano GRX/XTR Di2 “mullet” setup with an e13 Helix cassette is also offered), Argonaut’s own sub-1,300 g D33 wide-profile semi-aero carbon fiber rims laced with DT Swiss Aerolite spokes to Carbon-Ti X-Hub SP hubs, an Enve carbon bar and stem (with fully internal routing), Silca bar tape, an Enve carbon seatpost topped with a Selle Repente Artax GLX carbon-railed saddle, and Schwalbe G-One RX Pro tubeless tires.

Geometry-wise, the Supernaut GR3 most definitely leans toward the sportier side of things, but with a healthy dose of rowdiness to keep things spicy.

Fans of more progressive geometries might find the Supernaut GR3 to be kind of short in terms of reach, and going strictly by the numbers, it is. For example, a 56 cm Supernaut GR3 sports a 385 mm reach dimension, whereas even a medium Santa Cruz Stigmata is 405 mm. A large Stigmata is longer yet at 420 mm. As such, somewhat long-ish stems will be norm on a Supernaut GR3, but that reach figure doesn’t tell the whole story.

Argonaut uses an unusually slack 68.5° head tube angle almost across the board – a full degree slacker than the Santa Cruz – and combines that with an unusually generous 57 mm fork rake. The result is a fairly quick 74.4 mm trail dimension for agile steering, but also the long front center that fans of progressive gravel geometry want for more confidence on steep and/or tricky terrain.

“The front end geometry is intended to give the bike stability at high speed over bumpy terrain but also put the rider more ‘in’ the bike rather than on top of it,” Farver explained. “In testing we knew we wanted the bike to have a slack front end and make it handle more like a cross-country mountain bike rather than a ‘cross bike, which is why we targeted the 68.5° head tube angle. We tested a number of different fork rakes, and the forks with less rake like 50 or 55 mm made the bike feel like it wanted to wander. Bringing the trail back down into the mid 70s tightened up the steering yet maintained the high speed stability.”

Argonaut officially approves the Supernaut GR3 for tires up to 700x50 mm front and rear, but yet the 415 mm chainstays are at least 5 mm shorter than just about anything else you’ll find with similar clearance to further bolster the bike’s agile personality. Down below, the 73-77 mm bottom bracket drops keep your center of gravity nice and low, while the ample top tube slope exposes plenty of seatpost (27.2 mm round, FYI) for more flex on bumps. Despite the short rear end, Argonaut says there’s also room for a 48T chainring.

Other features include UDH-compatible dropouts, an internal-type T47 threaded bottom bracket shell (with a titanium shell insert), titanium inserts in the head tube to provide more precise seats for the headset bearings, fully internal routing using Enve’s In-Route system, and a molded rubber guard on the underside of the down tube to protect against rock strikes.

Accessory mounts are befitting to the bike’s go-fast mission and pretty limited in number, with spots for two bottle cages inside the front triangle, another on the underside of the down tube, bosses for a top tube feed bag, and that’s it. Sorry, no fenders for you.

Argonaut builds the Supernaut RM3 road bike with higher-modulus fibers since those bikes are less likely to see direct impacts (not to mention the fact that low weight and high stiffness are more highly prized on the road). The Supernaut GR3 gravel bike, on the other hand, features more medium-modulus content to impart more durability in day-to-day abuse.

“The RM3 is made up of a high-modulus fiber that we found to be the happy medium between stiffness and durability,” Farver told me. “We offer a 10-year warranty on our frames and want them to handle a lifetime of hard riding. Durability and longevity are key for us. We use standard-modulus fiber in the GR3 because we want the GR3 to stand up better to rock strikes and impacts. The GR3 is a little heavier than the RM3 but much more durable, as it should be.”

“Heavier” is relative, of course. Farver says that my 530 mm test frame comes in at just 940 g with paint, while actual weight for the complete build is a paltry 7.44 kg (16.40 lb) without pedals or accessories.

I know what you might be thinking at this point. Surely a “stock” bike that’s nearly US$16,000 and offers minimal customization can’t possibly be much more than something for rich people to show off to their friends, right? Is there any real substance here?

Spoiler alert: I generally try to avoid using profanity in my writing, but I’m hoping you’ll allow me this one indulgence because holy fucking shit, is this bike amazing. In fact, it’s not just amazing; it’s hands-down the best-riding gravel bike I’ve ever had the pleasure to throw a leg over.

Ride report: OMG

I’ve been describing in words how bikes feel for more than 20 years now. However, it’s still difficult for me to convey just how superbly the Supernaut GR3 rides, and I don’t think anything I write here will properly do the thing justice.

Keep reading with a 7-day free trial

Subscribe to n-1 to keep reading this post and get 7 days of free access to the full post archives.